Aplikasi

The roller congcot bit teh alat paling loba dipaké dina pangeboran minyak bumi jeung pangeboran géologis.Tricone bit boga fungsi impacting, crushing jeung shearing batu dina formasi, ku kituna bisa adaptasi jeung lemes, sedeng jeung formasi teuas.Bit congcot bisa dibagi kana panggilingan (waji waja) bit congcot jeung bit congcot TCI nurutkeun jenis huntu.

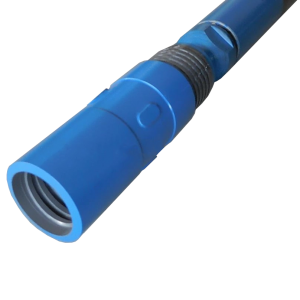

Ciri

Numutkeun bahan motong, éta bisa dibagi kana huntu baja (giling huntu) jeung tungsten carbide sisipan (TCI) huntu roller congcot bit.

The TCI Tricone bit pangeboran pikeun sedeng pikeun formasi batu teuas.

Formasi sedeng TCI tricone bit pitur sisipan tungsten carbide agrésif dina barisan keuneung sareng barisan jero.

Desain ieu nyadiakeun laju pangeboran gancang sarta ditambahkeun durability struktur motong dina sedeng pikeun formasi teuas sedeng.The HSN karét O-ring nyadiakeun sealing nyukupan pikeun bearing durability.

The formasi teuas TCI tricone bit bisa dipaké pikeun bor formasi teuas tur abrasive.Ngagem lalawanan tungsten carbide inserts dipaké dina baris luar pikeun nyegah leungitna bit gauge.Jumlah maksimum inserts ngawangun hémisferik dipaké dina sakabéh baris nyadiakeun durability cutter jeung umur panjang.

Struktur bit Tricone

Pituduh tina Tricone Bit Pilihan

| IADC | WOB(KN/mm) | RPM(r/mnt) | FORMASI LAKU |

| 114/116/117 | 0.3~0.75 | 180~60 | Formasi pisan lemes kalayan kakuatan compressive lemah sareng drillability tinggi, kayaning liat, mudstone, kapur tulis, jsb. |

| 124/126/127 | 0.3~0.85 | 180~60 | Formasi lemes kalayan kakuatan compressive lemah sareng drillability tinggi, kayaning mudstone, gips, uyah, kapur lemes, jsb. |

| 134/135/136/137 | 0.3~0.95 | 150~60 | Lemes nepi ka formasi sedeng kalawan kakuatan compressive lemah sareng drillability tinggi, kayaning shale lemes sedeng, gips teuas, kapur lemes sedeng, sandstone lemes sedeng, formasi lemes kalayan interbed harder, jsb. |

| 214/215/216/217 | 0.35~0.95 | 150~60 | Formasi sedeng kalawan kakuatan komprési tinggi, kayaning shale lemes sedeng, gips teuas, kapur lemes sedeng, sandstone lemes sedeng, formasi lemes kalayan interbed harder, jsb. |

| 227 | 0.35~0.95 | 150~50 | Formasi teuas sedeng kalawan kakuatan compressive tinggi, kayaning shale abrasive, kapur, sandstone, dolomit, gips teuas, marmer, jsb |

| Catetan: Wates luhur WOB sareng RPM dina tabel di luhur teu kedah dianggo sakaligus. | |||

Pituduh tricone Bits PilihanTricone bits Huntu Tipe

Ukuran Bit

| Ukuran Bit | API REG PIN | Torsi | Beurat | |

| Inci | mm | Inci | KN.M | Kgs |

| 3 3/8 | 85.7 | 2 3/8 | 4.1-4.7 | 4.0-6.0 |

| 3 1/2 | 88.9 | 4.2-6.2 | ||

| 3 7/8 | 98.4 | 4.8-6.8 | ||

| 4 1/4 | 108 | 5.0-7.5 | ||

| 4 1/2 | 114.3 | 5.4-8.0 | ||

| 4 5/8 | 117.5 | 2 7/8 | 6.1-7.5 | 7.5-8.0 |

| 4 3/4 | 120.7 | 7.5-8.0 | ||

| 5 1/8 | 130.2 | 3 1/2 | 9.5-12.2 | 10.3-11.5 |

| 5 1/4 | 133.4 | 10.7-12.0 | ||

| 5 5/8 | 142.9 | 12.6-13.5 | ||

| 5 7/8 | 149.2 | 13.2-13.5 | ||

| 6 | 152.4 | 13.6-14.5 | ||

| 6 1/8 | 155.6 | 14.0-15.0 | ||

| 6 1/4 | 158.8 | 14.4-18.0 | ||

| 6 1/2 | 165.1 | 14.5-20.0 | ||

| 6 3/4 | 171.5 | 20.0-22.0 | ||

| 7 1/2 | 190.5 | 4 1/2 | 16.3-21.7 | 28.0-32.0 |

| 7 5/8 | 193.7 | 32.3-34.0 | ||

| 7 7/8 | 200 | 33.2-35.0 | ||

| 8 3/8 | 212.7 | 38.5-41.5 | ||

| 8 1/2 | 215.9 | 39.0-42.0 | ||

| 8 5/8 | 219.1 | 40.5-42.5 | ||

| 8 3/4 | 222.3 | 40.8-43.0 | ||

| 9 1/2 | 241.3 | 6 5/8 | 38-43.4 | 61.5-64.0 |

| 9 5/8 | 244.5 | 61.8-65.0 | ||

| 9 7/8 | 250.8 | 62.0-67.0 | ||

| 10 | 254 | 68.0-75.0 | ||

| 10 1/2 | 266.7 | 72.0-80.0 | ||

| 10 5/8 | 269.9 | 72.0-80.0 | ||

| 11 1/2 | 292.1 | 79.0-90.0 | ||

| 11 5/8 | 295.3 | 79.0-90.0 | ||

| 12 1/4 | 311.2 | 95.0-102. | ||

| 12 3/8 | 314.3 | 95.0-102.2 | ||

| 12 1/2 | 317.5 | 96.0-103.0 | ||

| 13 1/2 | 342.9 | 105.0-134.0 | ||

| 13 5/8 | 346.1 | 108.0-137.0 | ||

| 14 3/4 | 374.7 | 7 5/8 | 46.1-54.2 | 140.0-160.0 |

| 15 | 381 | 145.0-165.0 | ||

| 15 1/2 | 393.7 | 160.0-180.0 | ||

| 16 | 406.4 | 200.0-220.0 | ||

| 17 1/2 | 444.5 | 260.0-280.0 | ||

| 26 | 660.4 | 725.0-780.0 | ||

Prosés Produksi

| Kuantitas Pesanan Minimum | N/A |

| Harga | |

| Rincian bungkusan | Paket Pangiriman Ékspor Standar |

| Waktos pangiriman | 7 dinten |

| Sarat pamayaran | T/T |

| Kamampuhan suplai | Dumasar Urutan Detil |